Counterfeit avoidance testing has become increasingly important for businesses to protect their reputation and ensure the safety of their customers. Counterfeit products not only damage a company’s brand, but they also pose serious risks to consumers. Implementing effective counterfeit avoidance testing is the best way to ensure that your business is protected from these risks.

Implementing effective counterfeit avoidance testing is to develop a plan outlining the procedures for identifying and preventing counterfeit products from entering your supply chain including guidelines for conducting thorough inspections of all products received and verifying the authenticity of each product a process for reporting suspected counterfeits and tracking any incidents that occur to identify any patterns or trends related to counterfeit activity and enable you proactive measures to prevent future occurrences.

Developed your counterfeit avoidance as6171 counterfeit avoidance testing plan, it is essential that you train your staff on how to implement it effectively. All employees involved in purchasing, receiving, or inspecting products should be trained on how to identify potential counterfeits and what steps they need to take if they suspect that a product may be fake. The staffs understand the importance of detecting and reporting counterfeit products promptly. Encourage an open culture where employees feel comfortable reporting any suspicions without fear of repercussions.

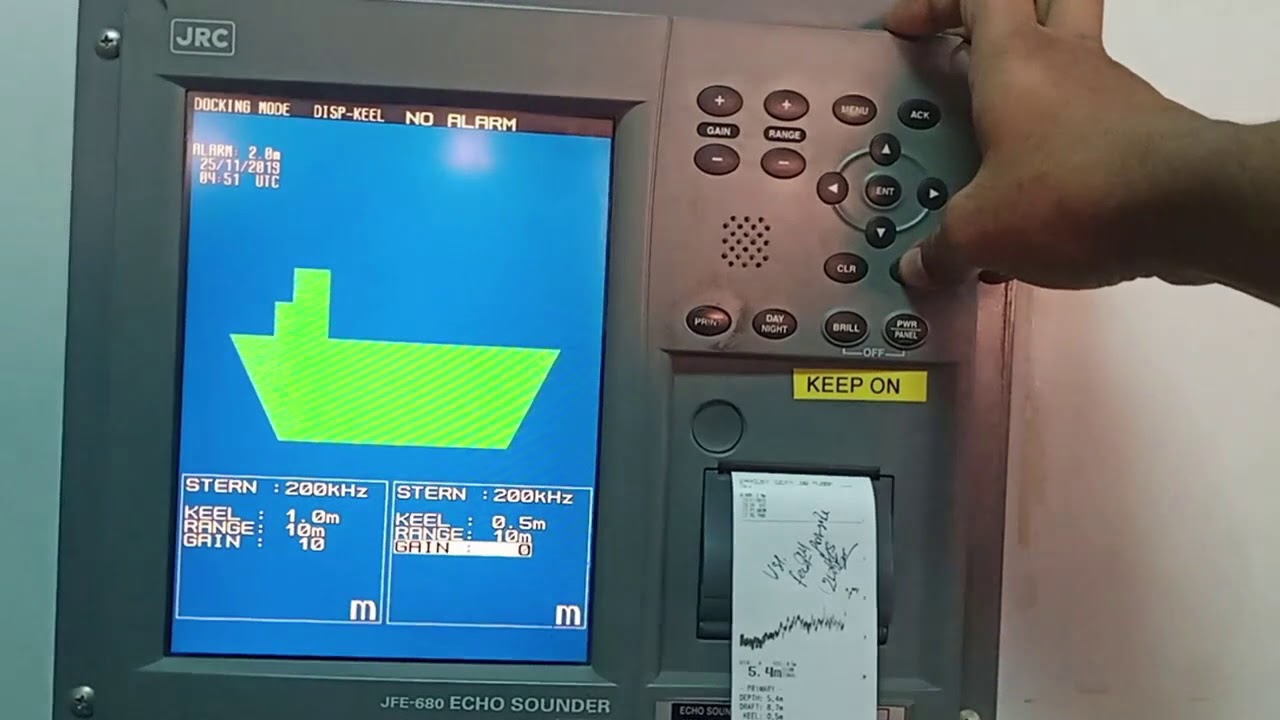

Technology plays a significant role in implementing effective counterfeit avoidance testing in your business. There are now tools available you verify the authenticity of products quickly and accurately. For example, there are handheld devices available that use advanced technology such as UV light, infrared imaging, or electromagnetic fields to detect whether a product is genuine or fake software systems that allow you to track and authenticate individual products throughout their entire lifecycle – from production through distribution and sale using unique identification codes or tags.

A crucial element of effective counterfeit avoidance testing is partnering with trusted suppliers commitment to quality and safety standards. Robust quality control processes in place, including regular audits by independent third-party organizations, seek out suppliers who are transparent about their supply chains providing detailed information about where their raw materials and how they source their finished products.

Conduct Regular Audits

- Conduct regular audits of all aspects of your supply chain from raw material sourcing through final product delivery to identify any vulnerability that could be exploited by counterfeiters.

- This includes reviewing supplier contracts regularly, inspecting incoming shipments thoroughly conducting random sampling checks on finished products shipments, and monitoring customer complaints closely for signs of counterfeiting activity.

Effective counterfeit avoidance testing requires vigilance, training, technology, strong partnerships with trusted suppliers, and ongoing monitoring through regular audits. By following these steps diligently and consistently over time, you protect your business’s reputation while ensuring the safety of your customers’ health and well-being.